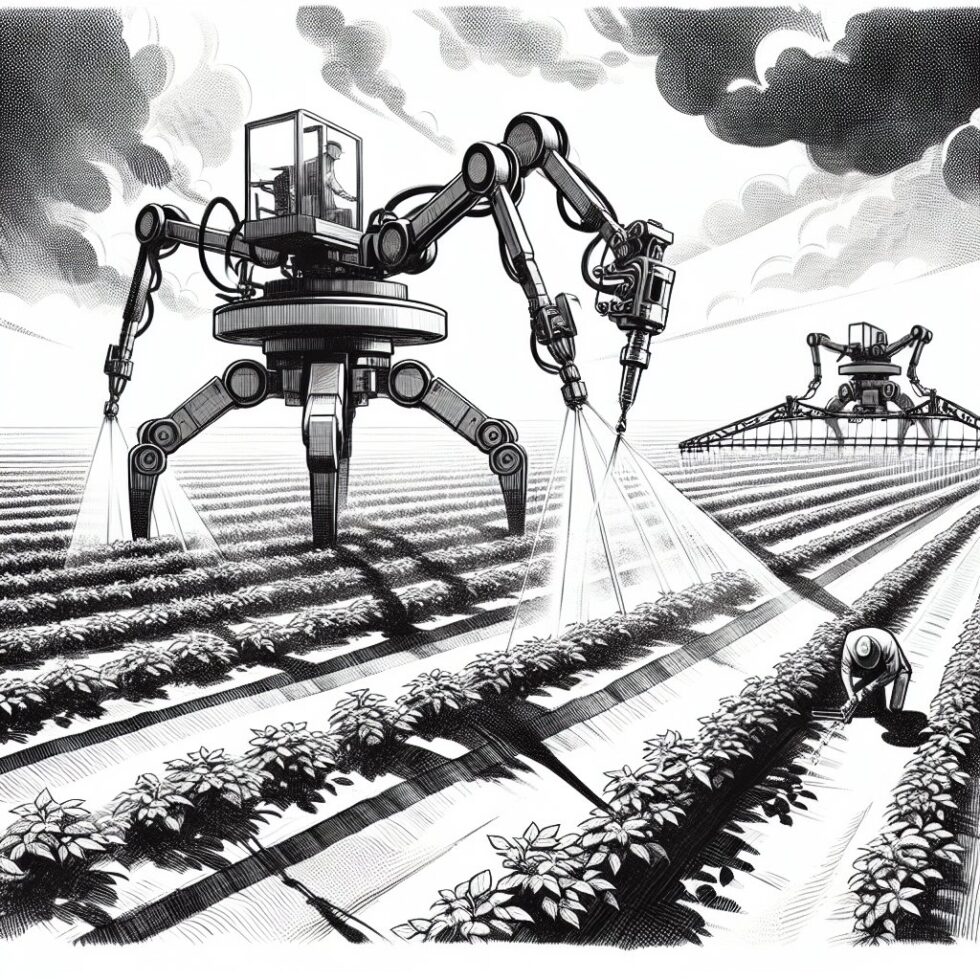

Farm robots are no longer a curiosity parked at trade shows. In the last few seasons, small teams have been rolling out machines that do specific jobs well: zapping weeds, spraying only the leaves that need it, and scouting fields on a schedule no human crew can match. The hardware is sturdier, the software is less fussy, and support options look like actual service contracts, not research projects.

This article is a practical tour of the field robotics that work today, and a plan you can follow to test and deploy them without taking on unneeded risk. We’ll cover the hardware inside, the jobs they’re best at, the budget math, safety must-haves, and the less glamorous details—maps, connectivity, and daily upkeep— that turn a good demo into a useful tool.

What Makes a Farm Robot Useful Today

Forget sci‑fi. The machines showing up on farms succeed because they focus on small wins, not general autonomy. The pattern is the same across vendors: good sensing, tight control, and clear limits. Here’s what that looks like under the hood.

Rugged sensing that handles dust, sun, and leaves

Most field robots see the world with a mix of RGB cameras and simple depth sensors. Some add short‑range LiDAR to sense rows and obstacles in low light. For crop care tasks, the key capability is green‑on‑green detection—picking a weed out of a crop canopy.

- RGB cameras for visual identification of leaves, stems, and soil.

- Depth sensors to keep tools at precise offsets and avoid plants.

- Lighting control (shrouds, strobes) to tame harsh midday sun and shadows.

- Simple bump bars and safety scanners to stop the machine if anything unexpected gets close.

These systems run computer vision models tuned to specific crops and growth stages. You don’t need to hand label thousands of images yourself. Vendors supply trained models and update them over the air between seasons.

Edge computing that doesn’t wait on the cloud

Everything critical runs on the machine. A robust compute module—often GPU‑equipped for real‑time vision—handles detection and control loops offline. Cloud connections, when available, are mostly for logs, maps, and updates. If the backhaul drops, the robot keeps working.

Mobility and power that match the job

Row‑crop machines favor narrow wheelbases and low weight to avoid compaction. Orchard robots emphasize traction on uneven ground and under‑canopy clearance. Most are diesel‑electric or fully battery‑electric for predictable operation and lower maintenance. Battery machines charge at the yard or in the field; diesel‑electric units carry their own generator for long days.

Supervised autonomy, not set‑and‑forget

Expect a human supervisor, especially during the first seasons. One person may monitor multiple robots, handle refills or bin swaps, and set up job boundaries. Think of it as “autopilot with a safety driver” rather than a replacement for skilled operators. The upside: once the routes and boundaries are dialed in, the cognitive load drops fast.

Safety and compliance built in

Look for emergency stops within arm’s reach, remote E‑stop, and geofenced zones the robot can’t leave. Machines that nod to standards like ISO 18497 (safety of highly automated agricultural machines) demonstrate a mature approach to risk. You want layered safety: sensors, software limits, and physical barriers when needed.

Where Robots Fit First: Jobs with Clear Payoffs

Field robots shine when the task is repetitive, time‑sensitive, and hard to staff. The three clearest wins right now: precision weeding, targeted spraying, and scouting.

Precision weeding: blades, micro‑doses, or lasers

Weed control is the poster child for robotic success because the value shows up fast. A vision‑guided robot can identify weeds and act in centimeters, not meters. You’ll see three approaches:

- Mechanical weeders with knives or brush tools that flick weeds without damaging crops. They work well when you want to avoid chemicals entirely and can tolerate slower ground speeds.

- Spot sprayers that put herbicide only on detected weeds. This can cut active ingredient usage by 60–90% in certain conditions, lowering cost and drift risk.

- Laser weeders that “cook” weeds at the meristem. They require careful smoke management and safety curtains, but deliver chemical‑free control, especially in organic systems.

For mixed weed pressure, robots can combine methods: blades for larger intruders, micro‑doses on tiny flushes the blades might miss. The key is repeatability: the machine shows up on schedule, even when labor is tight.

Targeted spraying: paint the leaf, not the field

Robots and smart implements can detect crop stress or weed presence and only spray where needed. In specialty crops, this reduces residuals and re‑entry concerns. In broadacre, it makes pre‑ and post‑emergent programs more precise. Modern systems use fast valves to fire nozzles in a fraction of a second as the boom passes. The results are measured in fewer tank fills, lower input bills, and cleaner maps of what happened where.

Scouting and mapping: eyes that never tire

Scouting bots carry cameras and simple multispectral sensors to spot emergence issues, gaps, and disease onset. They don’t replace agronomists; they give them better data and more hours back. With consistent routes and lighting, these machines build time‑series views of fields that highlight change, not just snapshots. Practical outputs include:

- Stand counts and gaps mapped early enough to replant or adjust inputs.

- Canopy vigor maps that flag irrigation or nutrient issues.

- Problem hotspots sent as work orders to spray or mechanical crews.

The Buying Checklist: How to Pick a Robot That Fits

Every farm is different. Use this checklist to filter your options before you schedule a demo day.

Field fit and task match

- Crops and spacing: Confirm row widths, bed shapes, and canopy heights the robot supports. Ask for proof in similar crops and growth stages.

- Ground conditions: Mud handling, slope limits, and turning radius matter more than brochure speeds.

- Implements: What tools or sprayers are included or compatible? Can you swap quickly between tasks?

Maps, guidance, and boundaries

- Guidance method: RTK GNSS is common; some add row‑following vision. Ask how it holds lines when GNSS dips under trees or near buildings.

- Boundary setup: Can you import shapefiles or ISOXML headlands? How fast is it to draw and lock a safe zone in the field?

- AB lines and repeats: Can it reuse last season’s guidance? Small conveniences add up over months.

Connectivity that’s practical, not perfect

- Local operation: The robot should run its job without any internet connection.

- Backhaul options: When available, LTE or farm Wi‑Fi for logs and updates is enough. Satellite is overkill unless you operate far from coverage.

- Updates: Over‑the‑air updates should be scheduled and reversible if something breaks.

Staffing and training

- Supervisor model: How many machines can one person monitor after the first week? What’s realistic in harvest season?

- Training time: Count hours until a new operator is safe and self‑sufficient, including boundary setup and daily checks.

- Support: Is there phone support during your working hours? Do they offer onsite service within a day?

Data handling and integrations

- Ownership: Do you own the data the robot collects? Can you export it easily?

- Formats: Look for common formats: shapefiles, ISOXML, or support for the AgGateway ADAPT framework.

- Privacy: If you don’t want your data used to train third‑party models, get that in writing.

Maintenance and uptime

- Daily checks: Filters, optics cleaning, battery charging—what’s the real routine?

- Wear parts: Cost and availability of blades, belts, nozzles, and fuses.

- Remote diagnostics: Can support see logs and sensor status to fix problems faster?

The Cost Math You Can Trust

Robots pencil out when they remove labor bottlenecks or cut inputs while keeping yields steady or better. Here’s a simple structure to evaluate ROI before you buy.

Start with the job, not the machine

Pick a single task that repeats over acres or blocks and has clear costs today. For example: an in‑row weeding pass in a high‑value vegetable field that currently takes six workers for three days, plus a follow‑up hand crew.

List the costs you’ll change

- Labor: Hours saved per pass and per season. Include supervision, training, and refills.

- Inputs: Herbicide or fertilizer reduction for spot application; fuel or electricity for the robot.

- Downtime: Expected lost hours due to weather or faults. Ask vendors for real, recent uptime data.

- Yield and quality: Conservative assumptions for reduced competition or better timing. Don’t overcredit.

- Financing and insurance: Monthly costs if you lease, plus coverage requirements for autonomous equipment.

Run a conservative season model

Model one season with worst‑case weather and a learning curve. If the numbers are still attractive, you can be confident. A realistic first‑year target is to replace 50–70% of the labor on a repetitive task. If a vendor promises 100% from day one, ask for references and uptime logs from similar farms.

Retrofit Kits: Turn Existing Equipment into Smart Implements

Buying a new robot isn’t the only route. A growing class of retrofit kits add precision sensing and actuation to sprayers, cultivators, and even harvest aids you already own.

- Vision‑guided tools: Camera bars and controllers that steer knives or fire nozzles only where needed. You keep your tractor; the kit handles the precision.

- Rate control and section control: Upgrading to fast valves and GPS‑driven sections can cut overlaps and boost accuracy instantly.

- Autosteer and autonomy modules: Some vendors offer supervised autonomy add‑ons for slow repetitive jobs—think bed shaping or mowing alleys—within geofenced zones.

Ask about ISOBUS compatibility (ISO 11783) so your existing displays and task controllers can interoperate. Kits are a lower‑risk way to capture some of the same benefits while you learn what autonomy fits your operation.

Safety: What Good Looks Like

Safe autonomy is a system, not a single sensor. The best vendors layer multiple protections and make it simple to do the right thing.

Controls and boundaries

- Hard‑wired E‑stops on both sides of the machine and on a remote pendant.

- Geofenced zones that the robot cannot leave, with a hard stop at the boundary.

- Speed limits by zone, especially near roads, buildings, and workers.

Perception and failsafes

- Dual sensing for critical functions: for example, both vision and proximity sensors must agree before tools actuate.

- Safe‑state defaults: If compute or comms fail, the robot stops and tools retract.

- Lighting and signage visible in dust and sun, with audible alerts during turns and tool actuation.

Ask vendors how they align with standards like ISO 18497 for highly automated ag machines, and how often they audit safety performance. Practice emergency drills with your crew before first deployment.

Connectivity and RTK: Keep It Simple and Reliable

Robots don’t need perfect internet, but they do need steady guidance. Many farms run a local RTK base station and use NTRIP to serve corrections over a short‑range connection. If you already have guidance on planters or sprayers, you likely have the infrastructure you need.

- Local RTK base: Steady corrections even when the nearest public tower is far or overloaded.

- Short‑range backhaul: Farm Wi‑Fi or LTE for logs and updates. The robot should not stall if it drops.

- Data hygiene: Back up guidance lines and boundaries. Small mapping mistakes create big headaches in autonomy.

Build vs. Buy: Who Should Roll Their Own

If you have an engineering team and a clear niche problem, building can make sense. The core building blocks—robot operating frameworks, inexpensive cameras, and embedded GPUs—are better and cheaper than ever. But support and safety take time. For most farms, buying a supported machine with a clear service plan is the faster, safer route.

What a build includes

- Software stack: A robotics framework, perception models, and tight control loops.

- Hardware integration: Sensors, compute, power, and actuators that survive dirt, heat, and vibration.

- Testing and safety: Hours in the field to harden edge cases and build robust failsafes.

A hybrid approach works too: retrofit vision kits now; build a specialized robot for a narrow chore later, once your team knows the pitfalls.

What’s Next (But Don’t Bet the Farm on It Yet)

Fruit and vegetable harvesting is the big prize, but also the hardest. Soft fruit varies in size and color; vines and branches shift with wind; and damage from rough handling is expensive. You’ll see impressive demos and pilot programs, and some commercial systems in controlled settings. Expect steady progress, not overnight change. Meanwhile, jobs with rigid targets and forgiving tolerances—like mowing, spraying, and weeding—will keep improving and spreading.

A Practical First‑Season Plan

Here’s a simple plan you can adapt for your operation.

- Pick one job with repeatable passes and clear costs today.

- Down‑select two vendors whose machines have proven results in your crop and region.

- Run side‑by‑side pilots on 5–10% of your acres or a few representative blocks for four to six weeks.

- Measure everything: labor hours, input usage, uptime, pass speed, and quality of results. Keep a simple daily log.

- Decide go/no‑go with conservative numbers. If it works at 70% of promised performance, you’ve got a winner.

- Scale with training: certify two operators and a maintenance lead before adding more units.

Real Examples to Watch

Several categories have credible offerings today:

- Laser weeding in specialty crops, with chemical‑free control on schedule.

- See‑and‑spray systems that reduce herbicide in fallow and green‑on‑green conditions.

- Autonomous row weeders with mechanical tools that protect crops in organic systems.

- Scouting platforms that produce stand counts and vigor maps for targeted interventions.

The common thread is tight focus. Each machine does one job, does it well, and integrates with the way you already work.

Common Pitfalls (and How to Avoid Them)

- Overpromising speed: Ground truth beats brochure numbers. Measure acres per hour in your fields, not test plots.

- Ignoring small setup costs: Time spent cleaning cameras and drawing boundaries adds up. Make it part of the ROI model.

- Forgetting safety drills: Practice E‑stops and refills with the crew. Make the safe way the easy way.

- Letting data pile up: Export maps weekly. Keep a clean folder for each field and pass. Garbage in, garbage out.

Why This Matters

Labor is tight. Input costs are volatile. Weather is less predictable. Robots don’t solve all of that, but they remove some pressure from the least forgiving weeks of the season. They let crews focus on skilled work. They turn big, blunt passes into small, precise ones. And they do it with data you can act on tomorrow, not a science project “someday.”

The most important point: you’re in control. Pick the jobs. Set the boundaries. Measure the results. Grow what works and pause what doesn’t. Field robots are now another tool in the shed—one that earns its keep when applied thoughtfully.

Summary:

- Today’s farm robots excel at focused tasks like weeding, targeted spraying, and scouting.

- Useful machines combine rugged sensing, edge computing, and supervised autonomy with layered safety.

- Evaluate fit by crop, spacing, ground conditions, mapping workflows, staffing, and service support.

- Build a conservative ROI model that includes labor, inputs, uptime, and training costs.

- Retrofit kits can deliver many benefits without buying a full robot.

- Safety is a system: E‑stops, geofences, dual sensing, and clear procedures.

- Connectivity should be practical—local RTK for guidance, simple backhaul for logs and updates.

- Start with a small pilot, measure carefully, and scale only when the numbers hold up.