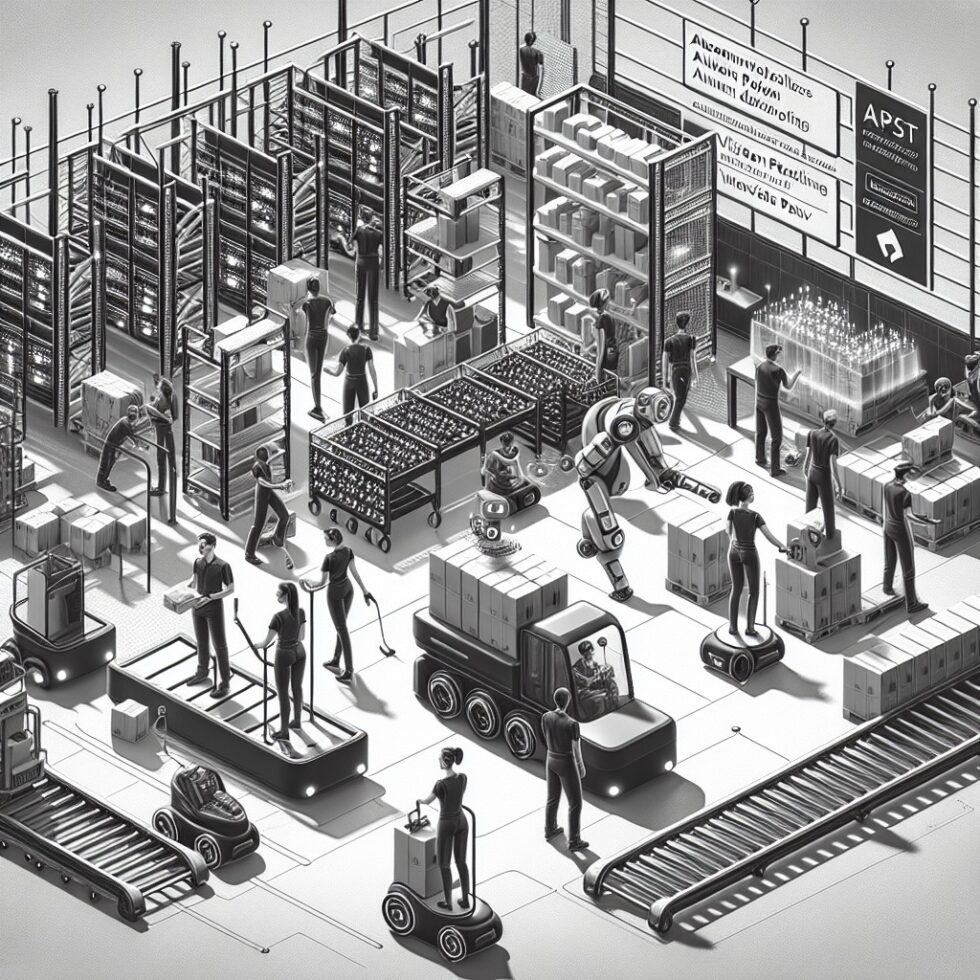

Online demand, short delivery windows, and tight labor markets have turned warehouses into the beating heart of retail and manufacturing. But the best upgrades aren’t magic showpieces; they’re practical systems that move goods consistently, day after day. This article lays out how modern warehouses actually automate work with tools you can deploy now: autonomous mobile robots (AMRs), vision-assisted picking, smarter shelves, and network choices that don’t fail when the building is busiest.

You’ll see where these tools fit, how they talk to your warehouse management system (WMS), the human factors that matter more than you think, and step-by-step playbooks for small, medium, and third-party logistics (3PL) operations. We’ll keep the language plain, the advice concrete, and the promises realistic.

The Real Work: What a “Smart” Warehouse Actually Does

Before gear, consider the flow. Most facilities share a backbone:

- Inbound: Unload, receive, inspect, and label. Goal: convert trucks into truthful, usable inventory.

- Putaway: Move items into storage with accurate locations and attributes (size, weight, hazard).

- Replenishment: Refill forward pick locations from bulk storage without starving pickers.

- Picking: Pull items for orders (single-line, batch, wave, or waveless). This step dominates labor.

- Packing and QC: Verify, right-size packaging, add inserts, and print labels.

- Sortation and Shipping: Direct items to carriers, routes, or zones efficiently.

- Returns: Inspect and sort returns to restock, refurbish, or recycle quickly.

Automation works when it directly supports one of these stages without creating a new bottleneck. That’s the lens to keep.

The Building Blocks: Systems You Can Actually Deploy

1) AMRs: The Workhorses That Cut Walking

Autonomous mobile robots (AMRs) move totes, pallets, or carts between zones. They differ from older AGVs by navigating dynamically using LiDAR and cameras rather than fixed tracks. In practice, AMRs reduce walking so people spend time picking, packing, and checking quality—not pushing carts.

Key points when you evaluate AMRs:

- Payload and form factor: Totes, shelves, pallets, or tugging trains. Pick what your inventory needs.

- Fleet management: Task assignment, traffic control, battery planning, congestion logic.

- Mapping and rerouting: Can it update maps when aisles shift? How fast does it adapt?

- Charging: Top-off vs. swap. Placement matters; don’t make charging a new chokepoint.

- Interoperability: Ask how it works with other vendors’ robots and your WMS.

AMRs work best in “person-to-goods” setups, where a robot brings a tote to a picker’s station or meets pickers at the end of an aisle to shuttle items forward. You’ll see immediate gains in a dock-to-stock workflow, where AMRs ferry received items to putaway with fewer interruptions.

2) Goods-to-Person vs. Person-to-Goods

Goods-to-person systems bring inventory to stationary workers using shuttles or AMRs. The benefit: consistent, ergonomic stations and high picks per hour. The tradeoff: higher capital cost and layout constraints.

Person-to-goods relies on pickers moving with assistance (AMRs, smart carts, voice direction). It’s cheaper to start and easier to reconfigure but tops out at lower throughput. Many operations use a mix: goods-to-person for high-velocity SKUs, person-to-goods for the slow movers.

3) Vision-Assisted Picking and QC

Vision is the “quiet power” that improves accuracy without heavy mechanics. Use handhelds or fixed cameras to:

- Verify picks: Computer vision checks shape, label text, or barcodes before confirmation.

- Detect errors early: Flag wrong items at the pick face, not at pack-out.

- Guide workers: Highlight the right bin or display arrows on a screen, like a visual “pick-to-light.”

- Record evidence: Snap a quick photo per order for customer support and auditing.

Vision tools live best at the edge to avoid latency. If connectivity is spotty, the system should cache and sync later. The result is fewer mis-picks and faster training for new hires.

4) Smart Shelves and Sensors

Simple sensors go a long way:

- Pick-to-light: A light on the correct bin reduces search time and errors.

- Weight sensors: Confirm that the right amount was removed or placed.

- Bin presence sensors: Help prevent “phantom inventory” when containers get relocated.

These systems don’t have to span the whole warehouse. Instrument your top 10–20% of SKUs by velocity, then expand.

5) Sortation Without the Overhead

Traditional sortation can mean conveyors and big capex. A middle ground uses AMR “sort walls”: humans handle exceptions and quality, robots move parcel bins between staging points. You keep flexibility and add lanes as volume grows.

6) Edge Compute Keeps Things Snappy

Even the best cloud platform can’t overcome milliseconds you waste waiting on the internet. Keep decision loops near the work with local controllers for AMRs, vision stations, and printers. With EdgeCompute in the mix, your system stays responsive during peak hours or spotty connectivity. Sync jobs and analytics can still flow to the cloud without slowing picks.

Safety, Ergonomics, and Work Design

Automation that creates new risks isn’t an upgrade. Build safety into daily flow.

Standards and Zones

Follow relevant standards for mobile robots and collaborative systems. Mark visual zones around charge points and crossing aisles. Use audible and light signals on robots. Your goal: visible intent. Workers should always know when a robot is approaching, stopping, or rerouting.

Ergonomics That Stick

Most injuries come from repetition and awkward movement. Keep forward pick bins within easy reach. Place heavy SKUs at waist height. Use lift assists for bulky items. If you add stationary workstations for goods-to-person, prioritize matting, adjustable heights, and good lighting. These choices reduce turnover and pick errors—small changes with big effects.

Recovery and Exceptions

Robots will stop when people block paths or sensors misread. Design a graceful fallback: clear, simple steps to move or pause totes, reroute jobs, and call support. Post the steps as a laminated sheet at each station. If recovery is a mystery, throughput vanishes when the building is busiest.

Networks That Don’t Drop Boxes

Your robots, scanners, and cameras live on wireless. Either it’s solid, or you’re paying people to reboot devices. Two proven approaches:

- Wi‑Fi 6/6E/7: Great for high bandwidth and handhelds. Invest in site surveys, channel planning, and fast roaming. Keep a clean SSID just for operational equipment.

- Private 5G: Strong coverage and mobility for AMRs across large facilities, yards, and dense metal environments. Use it for robots and critical control, and run guest or office devices on Wi‑Fi.

Many sites use both. Whatever you choose, test handoff reliability while AMRs drive their heaviest routes, and load the network with simulated peak traffic. Also, plan for local failover: if the backhaul dies, your edge controllers should keep picks and label prints moving.

Data Plumbing: Keep Inventory Truthful

Automation succeeds or fails on data hygiene. A warehouse needs shared truth among WMS, OMS, ERP, and carrier systems. Focus on:

- Master data quality: Dimensions, weights, hazardous codes, serial vs. lot. Bad data breaks robots.

- Event-driven updates: Confirm picks and moves as events, not nightly batches. You want real-time visibility.

- Cycle counts: Use AMRs or people to perform rolling counts so inventory stays trustworthy.

- Label discipline: Standardize barcodes and label placement to speed scanning and vision checks.

For integrations, ask vendors for MQTT or REST-based events and a straightforward mapping to your WMS. Avoid opaque “black box” connectors that hide what’s happening.

Where to Start: Pilot Playbooks

Pilot 1: Dock‑to‑Stock with AMRs

Target inbound putaway. Let AMRs shuttle received totes to storage. Keep humans on inspection and labeling. Success looks like:

- Metric: Dock-to-stock time cut by 30–50%.

- Scope: One receiving lane and a subset of SKUs.

- Duration: 6–10 weeks to reach steady state.

Pilot 2: Vision‑Verified Batch Picking

Add cameras or camera-enabled handhelds at the pick face. Confirm item visually and with barcodes before bin drop. Success looks like:

- Metric: Pick error rate down 60–80% on targeted SKUs.

- Scope: Top 10% velocity items where errors are most costly.

- Duration: 4–8 weeks including training.

Pilot 3: AMR Sort Wall for Outbound

Use AMRs to bring bins to a manual sort wall by carrier or region. Humans handle exceptions and label checks.

- Metric: Sort throughput up 25–40% with fewer missed dispatch cutoffs.

- Scope: One shift, one carrier group.

- Duration: 8–12 weeks with seasonal load tests.

How to Choose Vendors: Questions That Cut Through the Pitch

- Interoperability: Can your fleet manager dispatch different AMR brands? How?

- Open interfaces: Do you provide documented APIs and event topics? Sample code?

- Recovery steps: Show the recovery guide you give operators. Is it one page or a binder?

- Maintenance: What’s the preventive maintenance schedule and spare parts list? Battery life expectations?

- Security: How do you handle updates, device identity, and role-based access?

- Proof with your data: Will they run a pilot using your SKUs, labels, aisles, and network?

Costs, ROI, and Models That Fit

Automation can be capital equipment or a service. Both work. The right choice depends on volume stability and your balance sheet.

- CapEx: You own the robots and infrastructure. Lower long-term cost if volume is stable and you have in-house support.

- Robots as a Service (RaaS): Pay per month or per pick. Faster to start and easier to scale up or down.

Include more than hardware in your model:

- Integration, training, and internal change management.

- Network upgrades or spectrum licensing for Private 5G.

- Preventive maintenance, repairs, and spare units.

- Power, charging, and safety compliance (sprinklers, clearances).

Track a simple set of KPIs before and after:

- Throughput: Units or orders per hour by zone.

- Accuracy: Mis-picks per thousand lines.

- Cycle time: Dock-to-stock and pick-to-ship times.

- Labor utilization: Walking vs. picking time in sample observations.

- Safety: Recordable incidents and near-misses.

Keep the baseline honest. Walk the floor, time tasks, and photograph bottlenecks before you install anything. You’ll know if you’ve improved.

Keeping It Running: Operations You Won’t Regret

Preventive Maintenance and Spares

Schedule weekly checks for sensors, wheels, and lifts. Keep a small spare fleet for AMRs: one extra per 10–15 units is common. Calibrate cameras monthly. Keep lens wipes and battery testers at stations where people already pause.

Software Updates Without Surprises

Patch during the slowest shift. Try updates on two or three non-critical units first. Use staged rollouts and rollback plans. Keep a change log in the WMS or a shared site so supervisors know what changed and why.

Cybersecurity in Plain Language

- Put operational devices on their own networks with least privilege.

- Use strong device identities and rotate credentials regularly.

- Audit who can push updates and who can change workflows.

- Back up robot maps and WMS configurations offsite.

Sustainability That Also Saves Money

Greener warehouses don’t just look good; they reduce waste and costs.

- Charge smart: Schedule charging off-peak to reduce demand charges.

- Right-size packaging: Vision can measure parcels and choose fit-to-size boxes to cut void fill and freight costs.

- Reuse bins: Standardize totes and recycle broken ones. Label bins in consistent places to speed scanning.

- Return flows: Automate triage: resell, refurbish, or recycle with clear criteria to reduce backlogs.

Playbooks by Facility Size

Small Warehouse (under 50,000 sq ft)

- Start with scan discipline and simple pick-to-light on fastest movers.

- Add 2–5 AMRs to shuttle totes from receiving to putaway, and from picks to pack-out.

- Use vision at pack-out for final QC, not everywhere.

- Stick with cloud WMS plus small edge gateways for printers and cameras.

- Upgrade Wi‑Fi and carve a dedicated SSID for scanners and robots.

Mid‑Size (50,000–300,000 sq ft)

- G2P for top 10–20% of SKUs; person‑to‑goods plus AMRs for the rest.

- AMR sort wall for outbound peaks. Add dynamic slotting logic in the WMS.

- Mix Wi‑Fi for handhelds and Private 5G for AMRs if interference is severe.

- Introduce vision at both pick and pack for accuracy.

- Build a small, cross-functional automation team: ops lead, IT/network lead, safety lead.

3PL and High‑Throughput Sites

- Use a fleet orchestrator that speaks to multiple AMR brands.

- Designate “innovation aisles” for rapid pilots that won’t disrupt live lanes.

- Consider yard automation: dock door scheduling, yard trucks with geofences, and gate cameras.

- Expand observability: dashboards with queue lengths, robot utilization, and error hotspots.

- Automate reporting for SLAs per client and shift.

Common Pitfalls (and How to Avoid Them)

- Over-automating: Don’t mechanize broken processes. Fix layouts and data first.

- Ignoring change management: Train supervisors and mentors. Celebrate small wins.

- Dirty master data: Wrong dimensions and labels destroy accuracy. Audit early.

- Vendor lock-in: Favor open APIs and multi-vendor fleet options.

- Maintenance as an afterthought: Assign owner roles and stock spares from day one.

A Realistic Story: One Brand, Three Upgrades

Imagine a mid-size apparel brand with 120,000 square feet and a seasonal spike. Baseline data is honest: pickers average 110 lines per hour, mis-picks are 6 per 1,000 lines, dock-to-stock averages 8 hours, and too many orders miss the 4 p.m. carrier cutoff.

They start with three changes:

- AMRs on inbound: Robots move received totes to putaway, freeing receivers to focus on inspection and labeling. Dock-to-stock drops from 8 hours to 3.5 on day one of go-live.

- Vision at the pick face: Handhelds confirm items visually and via barcode on 20% of SKUs. Mis-picks fall to 2 per 1,000 lines in those zones within 2 weeks.

- AMR sort wall: Robots deliver bins to a manual wall sorted by carrier and zone. The team hits the 4 p.m. cutoff 97% of days, up from 78%.

Six months in, they add goods-to-person for top sellers. Average picker productivity climbs to 175 lines per hour in those lanes. Turnover falls because jobs feel less punishing. The biggest surprise isn’t the numbers; it’s the calm. Supervisors spend their time unblocking exceptions rather than chasing carts around the building.

What’s Next, Without the Hype

Near-term improvements are practical:

- Better multi-vendor robot orchestration so you can scale without lock-in.

- Faster, cheaper vision models running on small edge devices.

- Battery tech that extends runtime and safer charging options built into layouts.

- Smoother returns automation that triages items for restock vs. refurbish within minutes.

Focus on systems that make daily work steadier and safer. You want fewer interruptions, fewer surprises, and shifts that end on time—even on Mondays after promotions.

Quick Checklist to Start This Quarter

- Walk the floor and time tasks in receiving, picking, and packing.

- Clean master data for your top 15% SKUs by volume and cost.

- Pick one pilot: dock-to-stock AMRs, vision at pick face, or AMR sort wall.

- Plan networks: dedicated SSID or Private 5G for operations.

- Define 3–5 KPIs and a 10-week pilot plan with a rollback option.

Summary:

- Start where automation removes walking and errors first—AMRs and vision are proven, flexible tools.

- Blend goods-to-person for fast movers with person-to-goods elsewhere to balance cost and throughput.

- Keep decisions at the edge for low latency; use cloud for planning and analytics.

- Invest in safety, ergonomics, and clear recovery steps so performance holds under stress.

- Choose solid wireless: Wi‑Fi for handhelds, Private 5G for roaming robots, or both—you need reliable handoffs.

- Clean data and event-driven integrations keep inventory truthful and automation stable.

- Use focused pilots with honest baselines and simple KPIs to prove value before scaling.

- Plan for maintenance, spares, and cybersecurity from day one to avoid nasty surprises.