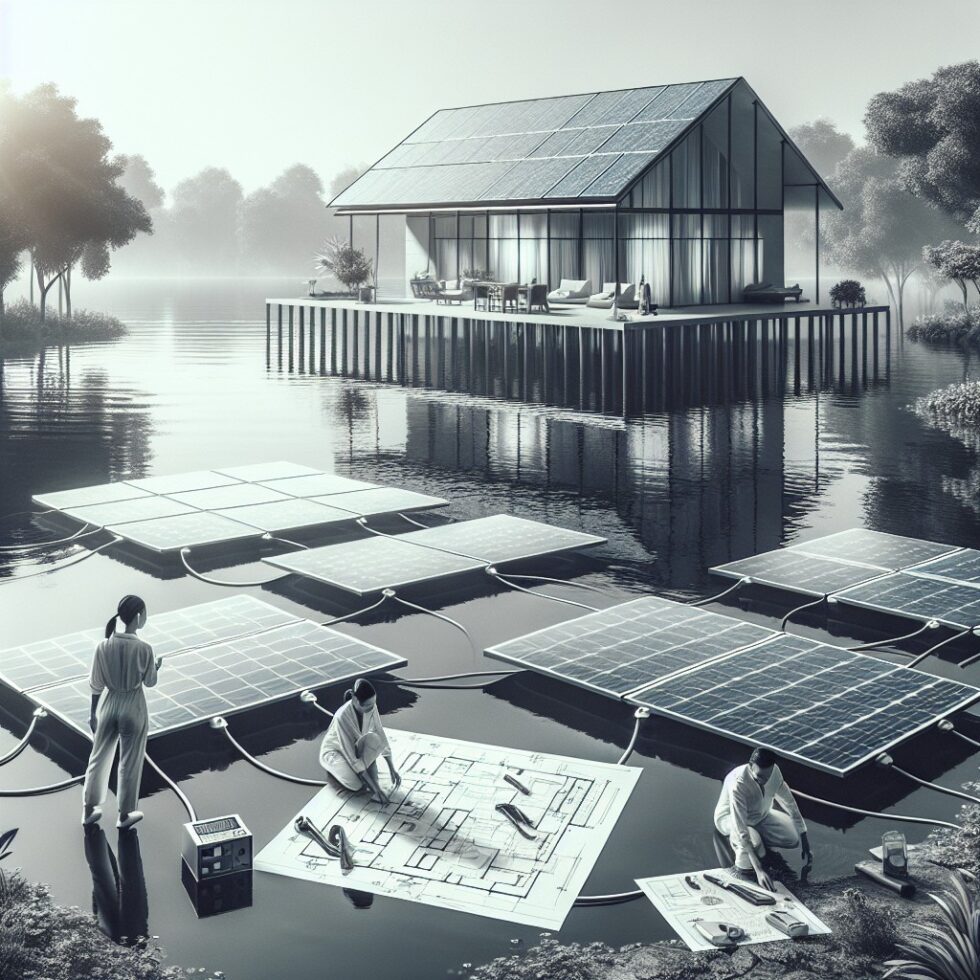

Floating solar is no longer only for big utilities. Small arrays on ponds and small lakes are becoming practical for homesteads, farms, vineyards, camps, golf courses, and community sites. You get clean electricity without giving up land, plus cooler panels that can produce a bit more power on hot days. Done right, a floating system can be quiet, low‑maintenance, and safe. Done wrong, it can be a hazard to wildlife and people.

This guide lays out a clear, practical approach. We’ll cover site checks, float and mooring choices, electrical architecture, and everyday operations. The goal is simple: help you build something that stays put, stays dry, and stays productive.

Is Floating Solar Right for Your Site?

Waterbody basics

Before you sketch a design, study the water. You need a stable surface most of the year and a place that’s easy to reach for maintenance.

- Size and fetch: The “fetch” is the distance wind can blow across the water. Longer fetch means bigger waves and more force on your array. On small ponds with fetch under a few hundred feet, well‑designed anchors and slack lines usually suffice.

- Depth and bottom type: Depth affects anchor choice. Mud holds helical or screw anchors well. Rocky bottoms favor deadweight blocks. Very soft silt may require over‑sized anchors or multiple sets.

- Water level swings: If levels rise and fall seasonally, your mooring lines must follow without pulling the array under. Plan for droughts, floods, and dam releases.

- Flow and inflows: Avoid placing arrays in channels with current, near spillways, or where debris piles up after storms.

Permits and neighbors

Rules vary. Some ponds are privately owned; others have overlapping water rights. Check with your local authority, water district, and utility. If you intend to grid‑tie, expect standard solar interconnection paperwork. If you have a homeowners association, discuss glare, seasonal appearance, and access paths early.

Environmental considerations

Floating arrays can reduce evaporation and algae growth by shading water, and they preserve land for crops or habitat. Still, be a careful neighbor to wildlife:

- Fish and plants: Shading part of a pond can cool water and shift plant growth. Avoid covering more than a small portion of the surface in small ponds.

- Birds and turtles: Avoid sharp edges and entangling netting. Provide gentle ramps on larger arrays, or place the array away from common basking sites.

- Water quality: Choose materials with proven resistance to leaching and UV breakdown. HDPE floats rated for potable water contact are widely used in floating solar projects.

Designing the Float and Mooring That Survive Weather

Float platforms

You need a structure that keeps modules level, drains splash quickly, and tolerates flex. Three common approaches suit small projects:

- Modular HDPE floats: Interlocking pontoons or trays designed for floating solar. They assemble fast, offer built‑in cable routing, and have known buoyancy ratings. They cost more, but they save time.

- Framed rafts on foam: Aluminum frames on closed‑cell foam logs. Lightweight and easy to customize, but foam must be fully encased and UV‑protected. Build with corrosion‑resistant fasteners and leave drainage paths.

- Deck‑style pontoons: Small dock sections adapted for solar. Great if you need walkway access for cleaning. Heavier, and you must proof the deck for wind and wave loads.

Whichever path you choose, ensure:

- Freeboard: Keep the deck a few inches above splash height. Add safety margin for wave action.

- Drainage: No place on the deck should trap water. Drains reduce weight shifts and slipping hazards.

- Non‑slip surfaces and handholds: If people need to step onto the platform, build in safe zones.

- Service channels: Reserve clearly marked cable paths and protected junction areas.

Mooring basics

Mooring keeps your array from drifting, twisting, or bumping the shore. It must marry strength with a little flexibility so the structure can move with water. For small ponds, this is typically a perimeter system: lines from the array corners to anchors spaced around it.

- Anchor types:

- Deadweight: Concrete blocks or steel weights. Simple, heavy, work on rock or hard bottoms.

- Helical/screw anchors: Twisted into mud or clay. High holding power per weight if installed correctly.

- Earth/stake anchors: Driven into firm soils. Often used near shore for perimeter mooring.

- Line choices: Use low‑stretch rope (e.g., polyester) with abrasion protection where it crosses rough edges. Sized generously; more diameter adds durability.

- Hardware: Stainless shackles and thimbles reduce wear. Add chafe guards where lines bend.

- Elastic elements: In gusty sites, mooring compensators or short sections of shock cord can ease shock loads.

Keep lines at gentle angles. Steep angles pull the raft down. Leave enough slack for water‑level changes and light rotation without rubbing against the shore. For small arrays, four to eight lines are common. Redundancy matters: a single failure should not release the whole array.

Storm handling and quick checks

Design for your worst realistic day, not your average afternoon. Strong winds and short‑period waves on small lakes still pack force.

- Orientation: Point the short edge of the array toward prevailing winds to cut force. Flat or low tilt reduces wind pressure. If you need tilt, keep it modest and uniform.

- Rule of thumb: Double check every link in the load path—anchor, shackle, line, cleat. If any single part fails, what happens next? Add backups.

- Inspection routine: After a major wind event, check line tension, chafe points, connectors, and float chamber integrity. Keep a simple log.

- Vegetation control: Remove floating debris and cut back reeds that can snag lines.

Electrical Architecture You Can Trust

Module choice and layout

Standard crystalline modules work well on water. Cooler operating temperatures are a quiet advantage. A few practical notes:

- Tilt: Flat arrays are simpler on water and reduce wind loads. If you tilt, 5–10 degrees helps shedding rain and bird droppings without adding much sail area.

- Walkways and gaps: If you plan to step onto the array, leave safe walking lanes and non‑slip surfaces. Gaps also allow air flow and make cleaning easier.

- Bifacial: Some floating designs use bifacial modules to capture light reflected by water. Gains are site‑specific and modest on small ponds; test one string before committing.

Wiring on water: keep it dry, keep it simple

Water and electricity demand extra care. Build like a boat electrician and a solar installer combined.

- Cable and connectors: Use UV‑resistant, tinned copper marine cable for runs on or near water. Use PV‑rated connectors and junction boxes with at least IP67 ingress protection.

- Routing: Use cable trays or conduits lifted above the deck. Add drip loops so water can’t run straight into enclosures. Secure cables every 12–18 inches with UV‑stable supports.

- Junctions on land: Make major splices and transitions at a shore‑mounted pedestal, not floating. Keep any combiner boxes on land when possible.

- Bonding and grounding: Bond metallic frames per code. Use corrosion‑resistant grounding lugs. Keep bonding conductors short and direct.

- Ground fault and leakage: Include DC ground‑fault protection where required and a leakage current detector if your inverter supports it. Water raises the stakes.

Inverters and interconnection

Pick an architecture that reduces DC risks on the water and matches your goals.

- Microinverters on the raft: They convert DC to AC at each module. This reduces high‑voltage DC runs across water and can simplify rapid shutdown. Mount them high and dry, in shaded locations with ventilation.

- String inverter on shore: Keep the high‑voltage DC run as short as possible and inside protected conduit. Use module‑level rapid shutdown devices if required by your local code.

- Off‑grid: For aeration pumps, lights, or remote loads, an MPPT charge controller with a battery bank can live on shore. Keep battery enclosures dry, ventilated, and away from flood lines.

Consult your local code and a licensed electrician for interconnection, overcurrent protection, and disconnects. Many jurisdictions follow NEC Article 690 for PV systems, which covers labeling, rapid shutdown, and grounding. When grid‑tying, also check your utility’s rules for meter upgrades and anti‑islanding.

Corrosion and materials

Water accelerates corrosion. Choose materials for the long term.

- Fasteners: 316 stainless steel resists rust in fresh water. Avoid mixing dissimilar metals without isolation washers.

- Frames and rails: Marine‑grade aluminum with isolation pads at contact points ages well.

- Conduit and enclosures: UV‑rated PVC or coated aluminum for conduit. Enclosures rated NEMA 4X or IP66+ for shore boxes near splash zones.

Safety zones and signage

Mark a no‑swim zone around the array. Post simple signs at access points: “No diving,” “Electrical equipment,” and a contact number. Keep a life ring on a pole within reach. When working on the array, wear a personal flotation device and use a stable boat.

Operations: Monitoring, Cleaning, and Seasonal Care

Monitoring that matters

Monitoring helps you catch small problems early. Start simple and add as needed:

- Power and voltage: Your inverter’s app (or a simple energy meter on off‑grid systems) shows real‑time and daily output. A sudden drop often means a connector, shading, or soiling issue.

- Mooring tension and angle: A quick visual check of line sag is enough for most sites. For windy lakes, you can add inexpensive tilt sensors on the frame and a load cell on one line to track changes after storms.

- Water level: A staff gauge on a post near the array gives you instant context for line slack and access planning.

Cleaning and biofouling

Floating arrays see bird droppings and spray. Keep it routine:

- Schedule: Brush or rinse modules as needed, usually monthly in bird‑heavy areas. Use soft brushes and deionized water if available. Avoid soaps that leave films.

- Access: Clean from a stable dock or boat. If you must step onto the array, use designated walkways and wear non‑slip shoes and a PFD.

- Biofouling: Inspect floats and lines for algae or zebra mussels in affected regions. Gentle scrubbing prevents added drag and weight.

Winter, drought, and drawdown

Cold climates bring ice. If your pond freezes solid, consider hauling the array to shore or mooring it in deeper water where ice moves less. In milder freeze‑thaw cycles, protect lines from abrasion at the edge. During drought, as water drops, re‑tune line slack to keep the raft clear of rocks and the shore.

Realistic Performance and Cost

Efficiency gains and honest expectations

Cooler panel temperatures can reduce losses on hot days. Studies often report a few percent gain for floating systems versus land‑mounted arrays due to better cooling and albedo effects. On a small pond, expect modest improvements, not miracles. The biggest practical benefits are space savings and easier siting on properties where land is constrained.

Losses and risks to watch

- Soiling: Bird droppings reduce output more than dust. Good cleaning access matters.

- Humidity and connectors: Moisture creeps into weak seals. Use quality connectors and keep junctions off the water.

- Chafe and fatigue: Mooring lines rub and flex daily. Chafe guards and routine checks pay off.

Budgeting a small build

Costs vary by site, but a simple framework helps you plan:

- Core hardware: Modules, racking or float system, anchors, lines, fasteners.

- Electrical: Inverters or charge controllers, cable, conduit, disconnects, labels, grounding hardware.

- Access and safety: Boat, PFDs, life ring, tools, cleaning gear.

- Permits and interconnection: Fees, inspections, and potential utility meter upgrades.

A modest 2–5 kW system with microinverters and modular floats will typically cost more than a similar land‑mounted array due to floats and mooring, but can be worth it where land is scarce or water cooling is a plus.

A concrete starter plan (example)

Imagine a 3 kW array on a quiet, 1‑acre pond with 8 feet average depth and short fetch. You choose six 500 W modules, two rows of three, mounted flat on modular HDPE floats. Each module has a microinverter mounted high under shade panels. Four perimeter mooring lines run to helical anchors, with two backup lines to shore posts. Cables run in raised trays to a shore pedestal where AC combines into a single run to the main panel with a code‑compliant disconnect. You add a staff gauge, a life ring, and a monthly cleaning routine. This setup trades a bit of tilt gain for simplicity and safety.

Checklist and Build Plan

Step‑by‑step, from sketch to switch‑on

- 1. Site survey: Measure fetch, depth, and water‑level swings. Map access points and prevailing winds.

- 2. Approvals: Confirm water rights, permits, and utility interconnection (if grid‑tied).

- 3. Layout: Choose flat or low‑tilt layout, walkway zones, and cable paths.

- 4. Floats and frame: Pick modular floats or build a corrosion‑resistant frame with protected foam.

- 5. Mooring design: Select anchors, place them to keep gentle line angles, and size lines with chafe guards.

- 6. Electrical design: Decide between microinverters on the raft or a string inverter on shore. Plan disconnects, grounding, and labeling.

- 7. Shore pedestal: Mount junctions and controls on land in a NEMA 4X enclosure above flood lines.

- 8. Safety: Mark a no‑swim zone. Stock PFDs and a life ring. Prepare an emergency plan.

- 9. Install: Assemble floats, set anchors on a calm day, then place and tie the array. Route and secure cables.

- 10. Commission: Test open‑circuit voltage, insulation resistance, ground continuity, and inverter startup per manufacturer steps.

- 11. Monitor: Log output, tighten lines after the first week, and set a recurring inspection and cleaning routine.

Frequently Asked Practical Questions

How much area can I cover?

On small ponds, keep coverage modest—often under 10–20% of the surface—to avoid big shifts in ecology and to leave open water for aesthetics and wildlife.

Will my panels blind my neighbors?

Solar glass is engineered to reduce reflection, but morning and evening angles can glare. Test with a single panel on a float for a few days, or simulate angles with a screen before full build. Low tilt and location away from sightlines help.

Can I anchor only to shore?

Yes, but shore‑only mooring is more sensitive to water‑level changes and can saw at the bank. Use protective sleeves and piers, or add at least one in‑water anchor for stability.

What about lightning?

Follow standard PV bonding and grounding. In lightning‑prone areas, discuss surge protection with your electrician. Keep conductors routed cleanly to earth and avoid loops that invite induced voltages.

Is there a quick way to estimate wind load?

For small arrays, a conservative shortcut is to size mooring lines and anchors as if they need to resist several times the weight of the entire structure in a gust. If you live in a high‑wind area, consult a marine or structural engineer for a more precise design.

Why Floating Solar Wins in Specific Cases

Floating solar will not beat a simple roof array on cost in many suburban settings. But it shines in a few clear cases:

- Land is valuable: Vineyards, orchards, or small farms where land is income.

- Heat is the enemy: Hot climates where cooler modules can offset some losses on peak days.

- Access is simple: A pond near the service panel makes runs short and maintenance by skiff easy.

When these align, the extra effort for floats and mooring pays off in usable space saved and a tidy, centralized installation.

Safety First: Simple Rules That Stick

- Never work alone on the water. Wear a PFD and use a stable boat or dock for maintenance.

- Keep junctions dry and accessible. Put critical electrical gear on shore, high and protected.

- Label everything. Clear labels help visitors, contractors, and first responders.

- Log inspections. A few notes after storms prevent surprises months later.

These habits matter more than any single hardware choice.

Summary:

- Floating solar saves land and can improve output on hot days; it suits ponds with modest fetch and stable water levels.

- Choose floats that drain well and resist UV; moor with redundancy and gentle angles to handle wind and waves.

- Design electrical systems to keep junctions on shore, use marine‑grade cable, and follow PV codes for grounding and shutdown.

- Plan for monitoring, routine cleaning, and seasonal checks for ice, drought, and line chafe.

- Budget for floats and mooring; small arrays cost more than land‑mounts but can be worth it where space is tight.

- Safety is non‑negotiable: PFDs, signage, disconnects, and a clear maintenance routine.

External References:

- NREL: Floating Solar Overview

- World Bank/ESMAP: Where Sun Meets Water – Floating Solar Market Report

- IEA PVPS: Best Practices on Floating PV

- U.S. DOE: Solar Inverter Basics

- NFPA 70 (NEC): National Electrical Code

- UL: UL 1741 Standard for Inverters and Interconnection Equipment

- NREL: Technical Potential of Floating PV on US Water Bodies

- US Coast Guard: Life Jacket Basics

- West Marine: Marine Wire and Terminal Tech Specs