Why “Where” Matters for Solar Now

Solar energy is no longer confined to sunny roofs and open fields. It’s moving onto reservoirs, into building materials, across canals, and into the guts of factory systems. The big story today is not a single breakthrough. It’s a set of practical upgrades that let photovoltaics work in more places with less friction. That means new formats, quieter hardware, better maintenance, and smarter integration with the grid and with heat systems.

The goal is simple: make solar fit where it once didn’t. That requires doing a few things very well. Keep modules cooler without adding moving parts. Make inverters act like good citizens on unstable distribution lines. Wrap PV into the surfaces we already buy for weatherproofing and daylight. And treat decommissioning and recycling as a design constraint, not an afterthought.

This article goes deep into those topics using clear language, practical examples, and up-to-date engineering concepts. We’ll explore floating arrays on water, building-integrated PV, inverter features you’ll hear more about, reliability and recycling, solar for industrial heat, solar over canals and carparks, interconnection “hacks” that work with the grid, and EV charging designed to soak up midday sun.

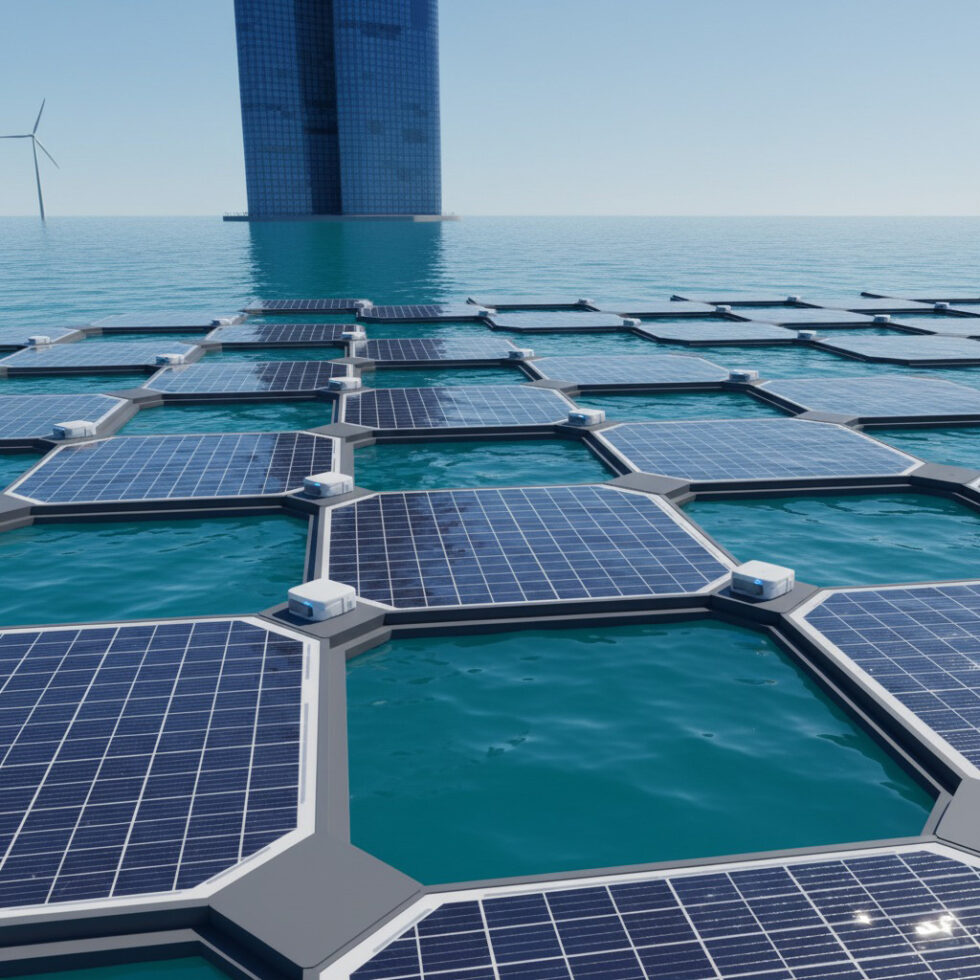

Solar on Water: Floating PV That Pulls Its Weight

Floating photovoltaic systems place standard or specialized PV modules on buoyant platforms anchored to the bed or shore of lakes, reservoirs, and water treatment ponds. The idea solves two siting problems at once: scarce land and waste heat. Water moderates temperature, and cooler modules convert sunlight more efficiently.

What changes on water?

Even a small temperature reduction can matter. Many crystalline silicon modules lose about 0.3% to 0.5% of power for each degree Celsius they heat up above their rating conditions. Over a long summer, a few degrees cooler can translate to a meaningful energy boost. Sites report modest but persistent gains compared with nearby ground arrays. The effect is site‑dependent but real.

Water also tamps down dust. Less dust means less soiling loss and less cleaning. That can be a major operating cost win in dry regions. And when floating solar is paired with existing hydroelectric dams, the two can share grid ties and operators. When the sun is bright, hydro plants can hold back water and use it later. The PV contributes energy; the dam contributes flexibility.

Anchors, waves, and storms

Floating arrays are mechanical systems first. The design challenge is to hold a large, flexible raft in place through daily wind and water motion, plus rare extreme storms. Mooring uses a mix of shore ties and weighted anchors, with lines that allow controlled motion but prevent drift.

- Redundancy: Use multiple lines and anchors so a single failure does not cascade.

- Geometry: Lay out the mooring with angles that spread forces. Avoid a single “downwind” anchor taking all the load.

- Freeboard: Keep buoyancy margins for added weight from rain and biofouling.

- Maintenance: Inspect hardware for corrosion and UV damage. Use materials rated for immersion and splash zones.

Electrical details matter too. Cables need extra slack for motion, abrasion protection, and watertight connectors. String voltages remain the same, but routing is different. Good floating designs put combiner boxes on raised walkways or shore to avoid high humidity and spray.

Ecological guardrails

Shade changes water chemistry. Less sunlight means cooler water and reduced algae, which is good. But too much shade can reduce photosynthesis and affect dissolved oxygen and fish behavior. Responsible projects keep coverage below thresholds recommended by local regulators, leave gaps for airflow, and monitor water quality. Non-toxic floats and wildlife‑safe geometry are not optional. The benefits—reduced evaporation, better energy yield, and no land use—are compelling; the job is to keep the side effects small.

Buildings as Power Plants: From Coating to Skin

Rooftop modules are the most familiar form of solar, but buildings can carry much more PV than their roofs might suggest. The trend is to make PV double as the envelope—a weather shell, a façade, a window.

Façade PV that architects can love

On the south face of a tall building, even modest efficiency can add up. Façade PV comes in two broad flavors: opaque cladding and semi‑transparent glazing. Opaque panels mount like rain screen cladding, with modules laminated onto durable backings. Their output is lower than tilted rooftop arrays, but so is the competition for space. The wiring hides behind the façade, and the building gains a clean, modern look.

Colored PV has matured. Instead of pigment that absorbs light (and energy), newer approaches use micro‑texture and coatings to reflect a narrow band of wavelengths that the cell isn’t efficient at converting. There is still an energy tradeoff; color rarely comes free. But the penalty is now small enough for many projects to accept, especially when the alternative is no PV on the façade at all.

PV windows without turning rooms into caves

Semitransparent PV is getting practical. It uses thin films to harvest part of the spectrum while passing the rest as daylight. The numbers are modest, but the combo is powerful: generate electricity and reduce cooling loads by filtering heat‑heavy infrared. Good glazing already saves energy; making it produce energy as well changes the math on large curtain walls. The trick is integration:

- Mounting and sealing must meet the same standards as any structural glazing system.

- Wiring needs hidden conduits that installers can access for replacement.

- Fire and egress rules govern where power runs inside the façade cavities.

Daylight quality matters. Designers can tune visible light transmission to maintain comfort and avoid glare. The best installations treat PV glass as part of the daylighting strategy, not an afterthought.

DC where it makes sense

Buildings are full of devices that run on DC: LEDs, electronics, and heat pumps with variable‑speed drives. Yet most buildings convert AC to DC at each device, adding cost and waste heat. A small but growing number of installations use DC buses on specific circuits like lighting or data rooms, fed directly by PV through DC-DC converters. This is not a whole‑building DC makeover. It’s a targeted step that shaves conversion losses and simplifies backup for critical loads. Done right, it also smooths PV’s interaction with batteries and reduces inverter stress.

Inverters Are Getting Good at “Grid Manners”

Inverters used to be simple: find the grid frequency and pump out power. Modern inverters behave like partners, not freeloaders. They can hold voltage, support frequency, ride through glitches, and help prevent cascading outages. Most features are software tuned but depend on robust power electronics.

Capabilities to ask for

- Volt‑VAR and Volt‑Watt control: The inverter senses local voltage and adjusts reactive and real power to stabilize the line.

- Frequency‑Watt control: When frequency droops, the inverter curtails slightly to help arrest the drop.

- Ride‑through: Instead of shutting off at the first flicker, the unit stays online within safe bounds, avoiding mass trips.

- Grid‑forming mode: Some inverters can set a stable voltage and frequency for a local island during outages. That turns solar from a fair‑weather friend into a backup source for critical circuits.

These features are wrapped into modern interconnection standards and utility requirements. They are also what enable tighter limits on exported power without sacrificing onsite consumption. When inverters respond gracefully, utilities can say yes to more rooftop and commercial PV on feeders that are already busy.

Microinverters, strings, and optimizers

There is no universal winner, but there are sensible defaults:

- Microinverters excel on complicated roofs with many directions and shade events. They localize failures and offer module‑level monitoring but add cost per watt.

- String inverters with DC optimizers balance cost and per‑module control. Optimizers help with shade and module mismatch.

- Plain string inverters with careful design are still the workhorse for big, uniform arrays. The gap with micro‑level devices narrows as string inverters gain better tracking and diagnostics.

One safety feature has gone mainstream: rapid shutdown. On buildings, the ability to de‑energize conductors near the array is now common practice. It protects firefighters and maintenance crews. Make sure any module‑level electronics you choose carry the correct ratings and certifications for your jurisdiction.

Reliability You Can Touch: Materials and Packaging

Small design choices add up to years of extra service. The most consequential trend in module hardware is simple: better packaging. Many manufacturers have shifted from glass‑backsheet to glass‑glass modules. Two sheets of tempered glass protect cells from moisture and keep them flat, reducing microcracks and “snail trails.” Encapsulants have shifted toward polyolefin materials that resist yellowing and block ions that cause potential‑induced degradation on hot, humid sites.

Failure modes worth learning by name

- Light‑induced degradation (LID): Some cells lose a bit of efficiency after first exposure. Modern cell processes control it better.

- Potential‑induced degradation (PID): High system voltage plus humidity can drive sodium ions into the cells, reducing output. Good encapsulants, grounding schemes, and biasing reduce risk.

- Backsheet cracking: Older polymer backsheets can craze and crack under UV and temperature cycles. Glass‑glass removes that weak point.

- Connector fatigue: Mismatched or poorly crimped connectors run hot. Use matched parts and proper torque; don’t mix brands.

Temperature cycling, humidity freeze, and damp heat tests in the lab don’t predict every failure in the field. But modules with strong test results, paired with mechanical frames that resist flexing under snow and wind, form the backbone of a low‑drama project.

Recycling and Circularity: Designing the Exit Before the Entry

PV modules are durable assets, but they don’t last forever. A thoughtful plan extends useful life and recovers value at the end. The trend is toward both repairability and recovery.

Design for disassembly

Modules are layered composites. That’s great for durability, hard for recycling. Newer designs consider future separation during manufacturing:

- Encapsulants that soften or dissolve under specific conditions, easing delamination without destroying cells.

- Frames and junction boxes that release without special tools, speeding disassembly.

- Lead‑reduced solders and lower silver content in pastes to cut both cost and environmental load.

On the operational side, tracking serial numbers and material declarations from day one makes later logistics easier. The more that installers, asset owners, and recyclers share data, the lower the cost of reverse logistics becomes.

What’s economically recoverable?

Glass and aluminum are straightforward to recycle and make up most of a module’s mass. Silver, copper, and silicon are smaller fractions by weight but higher by value. Emerging processes aim to gently take modules apart rather than shred them, preserving cells for potential reuse. Markets for refurbished modules in low‑demand applications—off‑grid, agricultural pumps, remote lighting—can extend life and defer recycling.

For inverters and combiner boxes, e‑waste practices apply. Clear labeling and easy access to components reduce time in the recycling stream. A take‑back program built into purchase contracts signals seriousness and helps vendors plan capacity.

Manufacturing Tweaks with Big Effects

Cell architecture evolves quickly, but you don’t need to be a device physicist to understand the practical implications. The move toward cells with lower recombination losses and better passivation has delivered higher module power at similar form factors. From a buyer’s perspective, a few trends stand out:

- Larger wafers and half‑cut or third‑cut cells reduce resistive losses and enable higher current at manageable temperatures.

- Bifacial modules harvest light from the front and reflected light from the back. They shine over bright surfaces or above light‑colored roofs and ground covers.

- Thicker glass and frost‑resistant frames matter in cold climates. In warm, humid ones, look for certifications that stress damp heat performance.

Behind the scenes, the industry keeps cutting the embodied energy and carbon of each module. Smelters and ingot grower facilities increasingly run on low‑carbon power. Manufacturers publish environmental product declarations so project owners can compare footprints. Choose reputable suppliers who back claims with third‑party data.

Solar for Heat: Low‑Friction Decarbonization for Industry

Electricity gets the headlines, but a large share of final energy is heat—water at 60°C for food plants, steam at 150°C for laundry, and higher for chemicals. Solar can supply a meaningful slice of that heat in three ways, each useful in different ranges:

- Flat‑plate and evacuated tube collectors for low to medium temperatures, common for hot water and process heat up to roughly 120–150°C.

- Simple concentrators like parabolic troughs for mid temperatures, often in the 150–250°C range.

- PV‑to‑heat using resistive heaters or heat pumps powered by PV for flexible integration and precise control.

Where it fits first

Industries that use steady, daytime heat at modest temperatures are natural matches: food and beverage, textiles, pulp and paper, laundries, and some mining operations. Roof heat collectors are low tech, low maintenance, and avoid the conversions from electricity to heat. For facilities already planning PV, adding a heat pump to lift 40–60°C water to 80–90°C can be more efficient than direct resistance, especially when the plant needs cooling too. The heat pump moves energy in both directions.

Thermal storage is simpler than you think

Hot water tanks and phase change materials store heat at low cost compared with batteries. They act like a sponge for sunny hours, letting a plant draw heat into the evening without juggling the power bill. For consistent processes, a couple of hours of thermal storage can carry a surprising share of the load and cut peak fuel use.

Solar Above Canals, Parking, and Paths

Covering canals with PV tackles land use and water loss. The shade reduces evaporation, and the canal’s embankments provide long, continuous rights‑of‑way that simplify permitting compared to new land acquisitions. The structures are bridges first and solar mounts second, so engineers size for wind and maintenance access to the water.

Carports and walkway canopies are the most accessible cousins to canal solar. They shelter people and cars and add a revenue stream for properties where roof structure or orientation isn’t ideal. From shopping centers to schools, a canopy array often becomes the flagship visible element of a community’s clean energy projects. The grid interconnection is close to the loads, and the foundations are standard construction skills.

Interconnection Without Headaches: Export Limits and Overbuild

Grid constraints are real. Transformers and feeders can only carry so much, and many regions have queues for new connections. Two design patterns reduce friction:

Non‑export or limited‑export designs

A system sized for on‑site loads can run with near‑zero export by measuring at the service entry and throttling inverters when output exceeds use. The array supplies what the building consumes and eases procurement because the utility sees lower risk. This approach can green campuses that were told “no export capacity left.” With a capable energy management system, the building still captures most of the solar benefit.

DC overbuild with smart curtailment

Modules are cheap relative to inverters. Oversizing the DC array compared with the inverter’s AC rating—then allowing controlled clipping—yields a fatter shoulder of production in mornings and late afternoons. The cost of the extra modules is paid back in higher annual energy and better use of the interconnection. If a site has limited export, the system can still feed full onsite loads over more hours.

Keeping Arrays Clean and Honest: O&M That Pays Back

Performance drifts slowly. Dust, bird droppings, and small failures nibble at output. Today’s operations and maintenance toolset spots those nibbles early:

- String monitoring highlights underperforming branches before the whole block sags.

- IV‑curve tracing during maintenance reveals mismatches and degradation without full disassembly.

- Thermal imaging by drone or handheld finds hot spots from bad solder joints or connectors in minutes.

- Robotic cleaning is common on large, dry‑dusty sites. Paired with hydrophobic coatings, it reduces water use and labor.

Data only helps if acted on. The best O&M teams close the loop by logging issues, tracking recurrence, and adjusting cleaning schedules by season and local conditions. A little humility about variance helps too: a string down on a cloudy day might look normal; check again in stable sun before rolling a truck.

EVs as Friendly Loads, Not Just Batteries on Wheels

Electric vehicles make millions of portable loads. Solar’s production peaks at midday. The match is excellent for workplaces and public lots. A few simple practices align the two:

- Default to daytime charging at offices and campuses. Cheaper rates plus clean power are a good pair.

- Dynamic charge rates let sites gently slow or speed charging to follow the sun and the building’s needs.

- Vehicle‑to‑home or facility can keep essential circuits alive during outages at locations with the right equipment. It’s a power quality problem first, a battery size problem second.

For most fleets, daytime charging with modest power is enough. The ladder truck or high‑mileage delivery van may need overnight AC plus some DC fast top‑ups. Smart scheduling beats brute‑force chargers in many cases.

Cost Is More Than Equipment: Design That Avoids Rework

A frequent cause of added cost is rework. Here are simple ways to avoid it:

- Involve facilities teams early. Roofers, electricians, and IT all touch the project. Surprises are rare when everyone sees drawings early.

- Choose common parts. Exotic racking or custom connectors tie you to one vendor’s schedule and prices for decades.

- Think about crane access for installation and service. A great array that can’t be reached without closing a road will be expensive to maintain.

- Label everything with weather‑resistant tags and keep a digital twin of wiring and serials. Troubleshooting time collapses when the map is clear.

What’s Quietly Next

Some innovations don’t need fanfare to matter:

- Back‑contact modules that hide busbars boost active area and reduce resistive losses, improving aesthetics and performance.

- Reflective and engineered ground covers under bifacial arrays raise rear‑side gains without significantly increasing maintenance.

- Upcycling retired modules for community centers, shelters, and remote sensors squeezes more public value from existing hardware before it enters the recycling stream.

- Factory‑integrated wiring harnesses reduce field errors and installation time on large sites.

Each is modest alone. Combined, they allow solar to seep into places it once missed: urban cores, water‑stressed regions, and industries that measure downtime in dollars per minute.

Putting It Together: A Checklist for Projects That Fit

Whether you’re planning a floating array for a reservoir, a façade PV retrofit for an office tower, or a limited‑export system for a crowded feeder, the same themes keep showing up. Use them as a sanity check:

- Make the site do some work. Use water cooling, bright ground cover, or canopy shade where you can. Take advantage of what’s already there.

- Design for maintenance. Choose parts and layouts that your local crews can service without special tools or heroic access.

- Favor inverter features over raw power. Grid support modes and clear monitoring often beat a few extra watts of peak output.

- Plan the exit. Document materials, include take‑back terms, and avoid glue that can’t be undone without destroying value.

- Match the energy form to the job. Heat collectors for heat. PV for power. Heat pumps where they can couple both sides.

- Keep export simple. If the grid says no, design for onsite use and revisit export later with data in hand.

Case Sketches: How These Ideas Play Out

The reservoir that feeds a town and a grid

A municipal utility covers a fraction of its reservoir with floating PV. The array connects to the same substation as the town’s water pumps and shares the hydro plant’s tie. Mooring lines use both shore anchors and weighted blocks to accommodate seasonal water level changes. The PV reduces evaporation and provides power that displaces peak purchases on bright afternoons. Water quality sensors alert operators if dissolved oxygen dips, triggering aerators. Over time, the town adds a second block and upgrades inverters with grid‑forming capability for backup of the pumping station during storms.

A mid‑rise office that earns its façade

A property owner replaces aging cladding with PV façade panels and semitransparent PV spandrels in the curtain wall. The system routes cabling through fire‑rated pathways to a central combiner. Inverters track local voltage and provide reactive power support to the feeder, which already hosts multiple rooftop arrays. Energy monitoring shows a reduced cooling load thanks to fewer IR gains, and tenants enjoy the daylight without glare. Maintenance is folded into the façade cleaning schedule.

A small factory that runs hot water on sun

A food processing plant installs evacuated tube collectors for 90°C water and a PV array for process controls and refrigeration. A hot water tank stores several hours of heat, cutting midday gas use to near zero. The PV array is oversized on the DC side and runs limited export to avoid a long interconnection study. A roof canopy extends over the loading dock, improving working conditions while adding generation.

Common Misconceptions, Quickly Debunked

- “Floating PV will choke lakes.” Not when designed well. Responsible coverage ratios and continuous monitoring keep ecosystems healthy, while reducing evaporation can be a net water benefit.

- “Façade PV isn’t worth it.” On its own, façade PV delivers less energy than tilted roofs. But on high‑rise footprints, it’s often the only large surface available and pairs with cooling savings.

- “You must export power for solar to pay back.” On sites with steady daytime loads, non‑export designs capture most benefits with fewer grid hurdles.

- “Batteries are required.” Helpful, yes, but many projects pencil out on self‑consumption, thermal storage, and thoughtful scheduling of loads like EV charging and hot water.

How to Start Without Waiting for a Perfect Plan

Solar succeeds by moving forward in steps. You do not need to solve everything at once. Start with a site walk and a list:

- Surfaces you control: roofs, façades, parking, water bodies, rights‑of‑way.

- Loads that can shift: water heating, ice storage, EV charging, noncritical HVAC.

- Interconnection facts: feeder capacity, acceptable export levels, nearby substations.

- Maintenance reality: staff skills, lift access, cleaning water availability.

Then pick the first step with the least dependency on external approvals. That is often a canopy, a limited‑export rooftop, or a process heat retrofit. Gather data from the first year. Use it to make the second step bigger and easier to approve.

Summary:

- Floating PV turns water surfaces into energy assets, with cooling, reduced soiling, and careful mooring and ecology management.

- Building skins—façades and PV glazing—unlock urban solar by doubling as weatherproofing and daylight control.

- Modern inverters provide grid support features that win approvals and improve power quality.

- Reliability gains come from better packaging, glass‑glass modules, robust encapsulants, and attention to connectors.

- Recycling and circularity improve with design‑for‑disassembly and take‑back programs that recover aluminum, glass, copper, and more.

- Solar heat pairs collectors, PV, and heat pumps to decarbonize low‑ to mid‑temperature industrial processes.

- Solar over canals and carparks saves land, reduces evaporation, and places generation near loads.

- Non‑export and DC‑overbuild strategies ease interconnection while maximizing onsite solar use.

- O&M tools—string monitoring, IV tracing, thermal imaging, and robotic cleaning—keep arrays at their best.

- EV charging aligned with midday sun turns vehicles into helpful loads that stabilize site demand.